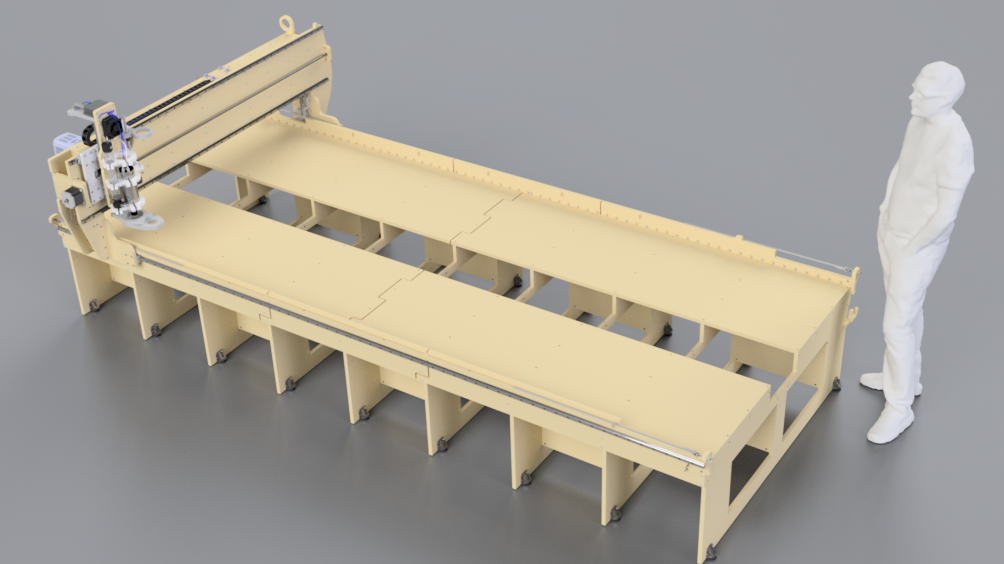

Discover our user-friendly large format CNC Router kit. It sets you up for quickly creating cabinets, signs, and a myriad of other projects. Our CNC router is constructed from Medium Density Overlay (MDO), a wood renowned for its exceptional resistance to high moisture levels. A space saving angled version is also available.

This CNC router has the capability of automated cutting, milling, drilling, 3D carving and pocketing (all subtractive fabrication). Materials that this CNC router can cut or engrave is soft metals (aluminum, brass, mild steel, wood of all types, plastics of all types, foam and other similar materials).

Machine Technical specifications:

Maximum Stock Size & Machine Envelope: Our CNC routers are designed to accommodate stock sizes equivalent to their specified dimensions (e.g., 4'x8', 5'x10'). The actual working envelope of the machine is larger, 25 inches wider and 40 inches longer (The extra length can accommodate a laser gantry). For instance, the greenBull v2 4'x8' model easily accepts a 4'x8'.

Z-Axis Travel: Features an impressive 7-inch travel on the Z-axis.

High-Performance Spindle: Equipped with a 220V 2.2kW spindle and VFD, ensuring powerful and efficient operation.

Mechanical Movement: The X-axis benefits from a roller chain and drive sprockets system, while the Y and Z axes operate on a precise 1/2" lead screw, ensuring smooth and accurate movement.

Robust Construction: The structure is based around MDO (Medium Density Overlay), complemented by an Aluminum Y carriage and Steel Rails conforming to HIWIN specifications.

Advanced Electronics: Includes either a Mach3 USB controller or a standalone CNC controller. All axes are powered by NEMA 34 0.5Nm (1200 oz-in) closed-loop stepper motors with matched drivers. Each driver is equipped with its own power supply for optimal performance.

The kit includes all of the wires and cables necessary to connect all of the electronics. A computer is not included. The table and bed structure is also included in the kit.

For those seeking a space-efficient solution, our 60-degree model is an ideal choice, boasting a compact overall width of just 63 inches for the 4'x8' model. This design is optimized for placement against a wall, requiring access from only one side, thus maximizing your workspace efficiency.

Accuracy and Precision

The resolution per axis is adaptable, allowing changes to the driver's microstepping settings. Typically configured to achieve over 1000 steps per inch, balancing mechanical and digital precision.

The X and Y axes employ tensioned roller chains, minimizing backlash and enhancing repeatability.

Accuracy is largely dependent on machine calibration and squaring. Squaring is streamlined, involving adjustments to the roller chain sprockets and the gantry back hardware. Once squared and relaxed, the hardware is secured to maintain permanent squareness.

Calibration is software-assisted and as accurate as the physical measurement system allows.

Shipping:

Please expect a delivery period of 3 weeks, as each machine kit is tailor-made for individual orders. These are shipped via freight in crates measuring roughly 96"x40"x30" and weighing approximately 600 lbs. Note that the shipping cost, around $500, is not included in the kit's price. You also have the option to arrange your own shipping, if preferred.

Some customer examples: