BuildYourCNC

The redFly CNC Electronics System

The redFly CNC Electronics System

Couldn't load pickup availability

Motor cable will need to be purchased additionally. Click Here For Motor Cable.

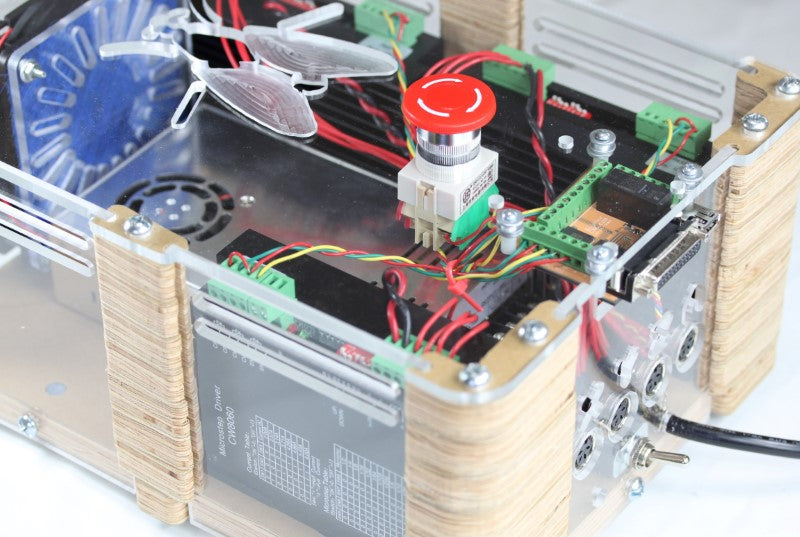

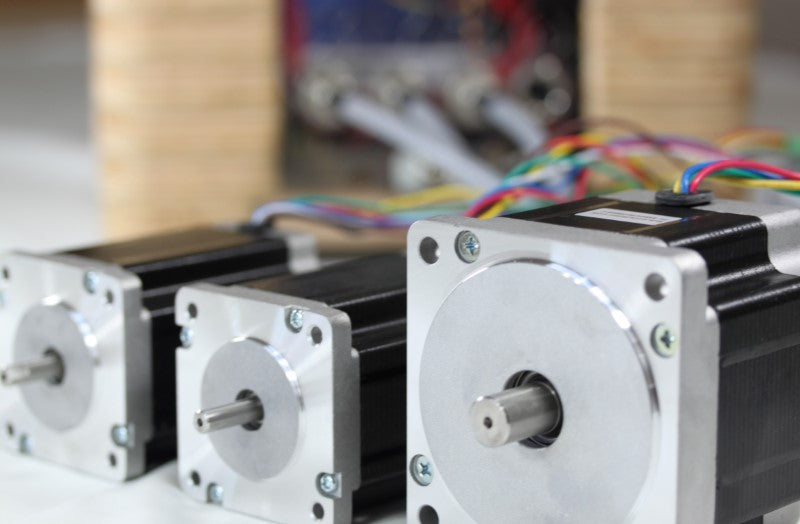

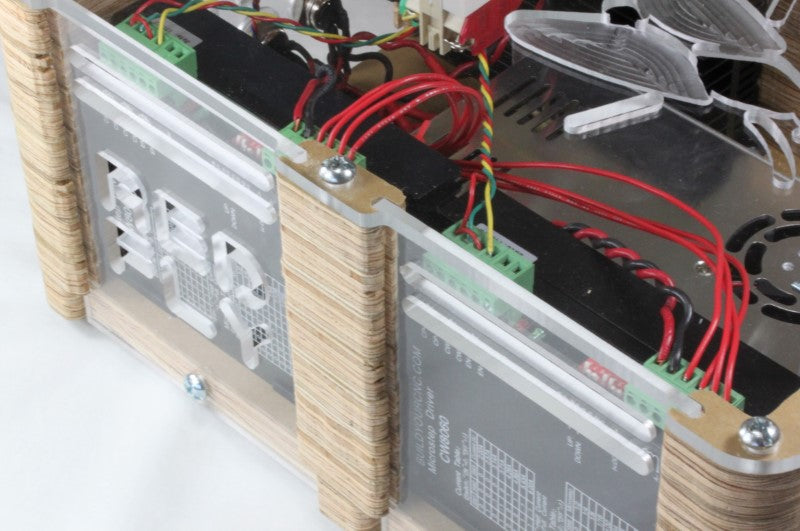

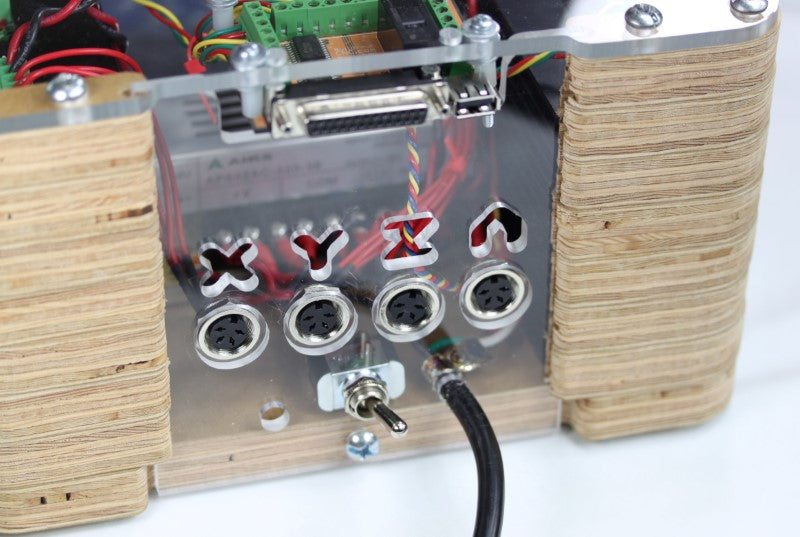

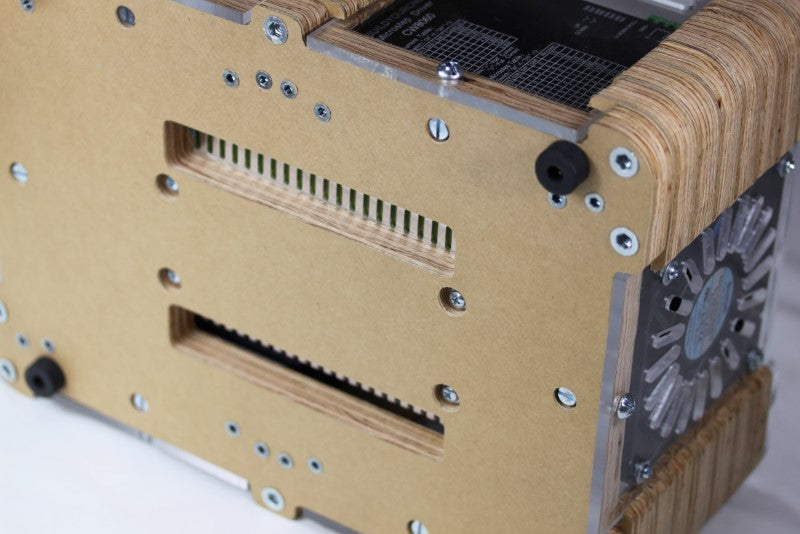

Actual motor tuning based on your machine will vary. In some instances you will have to calculate the steps per inch yourself or use the Mach3 automated steps per unit calculation process if we do not have the relevant information. The basic system (first purchase option) has three standard motors (425 oz-in torque) and drivers (3.0 amp per phase) which is perfect for small to medium CNC router or CNC machine, or general duty machines). The second option for Heavy Gantry includes two standard motors and drivers like the first option, but has a heavy duty motor (651 oz-in) and driver (5.6 amp) to move the gantry which is perfect for medium to larger CNC routers or machines with a heavy gantry at or about 100 to 200 lbs. The third option is for heavy duty machines that require large motors (651 oz-in) and drivers (6.0 amp) on each axis which is great for machines with heavy Z-Axis assemblies. With this package you receive: • Motor Drivers 40 Volts 3.0 Amps or 6.0 Amps Max (capable of 1/64 microstepping) depending on the option chosen • 425 oz-in or 651 oz-in bipolar motors depending on the option chosen • Mach3 USB Controller • 36 Volt 10 Amp Power Supply • Panel Motor Cable Connectors • Fan (Near the Middle) • Wood, Plastic and Fasteners in a Clean and Aesthetic Arrangement to Encase the System Under the case, the drivers have a special cut-out to allow for the flow of air to transfer the heat out of the enclosure. To provide this air flow, there is a large fan in centrally located. With a fan directing air into the enclosure, there is always positive pressure within this enclosed space. Openings were carefully positioned to exit the heat in the most appropriate way. Moreover, the positive pressure will limit the amount of dust that enters into the enclosure. The New Pokeys CNC Control System The new Pokeys CNC Control System includes three 6.0 amp drivers, the full featured Pokeys57CNC two 48V power supplies, 4 limit switches, two NEMA 34 651 oz-in stepper motors, one NEMA 24 425 oz-in stepper motor an emergency stop button,, and a fan to keep everything inside cool.Share

Questions & Answers

Have a Question?

-

I'm interested in using Mach4 and already have 3 motors (425 oz-in). Is it possible to get a electronics system without the motors?

Yes, I can furnish the redFly system without motors. You can request a quote for this at customerservice@buildlyourcnc.com

-

Is it possible to purchase this item with provisions for a 4th axis?

Yes, all you need to do is purchase an extra driver. If you are purchasing the 4th axis from us, you won't need to purchase a motor since the 4th axis already has a stepper motor in the assembly. If you have a 4th axis, make sure your 4th axis has a stepper motor, otherwise, you will need to purchase the appropriate motor. Driver: https://buildyourcnc.com/item/electronicsAndMotors-stepper-driver-6!0a

-

I have a probotix cnc router purchased in 2014, used to run on linyx, now Mach3, WindowsXP, printer port, i would like to be able to use a modern computer usb, do you have something like a plug & play or control box i can wire this into, 2 Y axis, i lost my auto tool length when i switched to XP also, any help appreciated

You have motors and drivers that already work with your machine (unless the drivers are an all-in-one setup and not modular. I would advise you to keep your current electronics and replace the parallel port breakout board with a controller that uses the USB to operate. Here are two controllers that work under Mach3, or Mach3 or Mach4: Mach3 USB controller (works under Mach3 only) https://buildyourcnc.com/item/electronicsAndMotors-electronic-component-breakout-Mach3-USB-Board Pokeys57CNC full-featured controller works under Mach3 or Mach4: https://buildyourcnc.com/item/electronicsAndMotors-electronic-component-breakout-Mach4-mach3-USB-ethernet-Board Alternatively, you can purchase a complete plug-and-play system or have your control system sent over to Buildyourcnc to modify the control system to use one of the above controllers.